Add to Cart

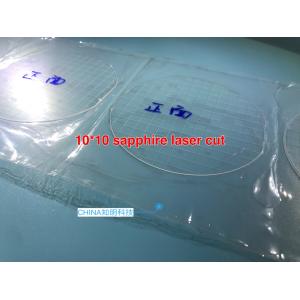

customized size 10x10/7x7mm sapphire glass laser cutting for phone camera protective lens

Micro cutting and drilling for cell phone cover, optical glass, sapphire, semiconductor, chip. Specific application:

1. Fingerprint indentification chips cutting. Cell phone plate and optical lens cutting.

2. Organic inorganic flexible display circuit etching and cutting.

3. Optical lens and LCD panel cutting

| TECHNICAL SPECIFICATIONS | |

| Model No | HRPC-50W Picosecond Laser Micro Cutting Drilling Machine |

| Laser wavelength | 355 nm UV |

| Positioning accuracy | ±3µm |

| Repeat accuracy | ±1µm |

| Processing Size | 250*250 mm |

| Cooling Way | Air Cooling |

| System Processing Precision | ±20µm |

| Vibration Acceleration | <0.05G |

| Focus Method | Following and Automatic Adjust Focus |

1. Picosecond laser with ultrashort pulse and no heat conduction, is suitable for high speed cutting and drilling organic or inorgannic materials. The min. chopping or heat affected zone is less than 10um.

2. One laser source with beam split technology, dual laser head processing with efficiency doubled.

3. CCD visual home target, one time process 650*450mm, stitching precision XY platform less than 3um .

4. Automatically cleaning, visual detection and sorting, automatic feeding and blanking.

Actual cutting effect